A new automated product warehouse was presented at the Nokian Tyres enterprise.

The Governor of Leningrad region Alexander Drozdenko estimated implementation of the investment project during his visit to the enterprise. “Since the very beginning Nokian Tyres announced that this will be the most modern factory. And indeed each new development phase they are one step ahead of the previous one and every time technologies for project implementation are higher. What we saw today is fantastic, we looked into the future,” commented Alexander Drozdenko.

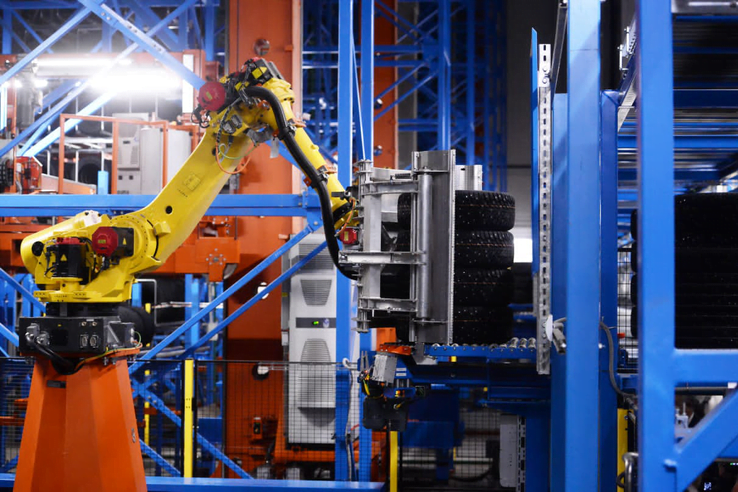

The new high-rise automated warehouse for finished products which is a part of the logistics complex of the company in Vsevolozhsk was commissioned in 2020. Its unique storage technology allows keeping up to 550,000 tyres at the area of only 16,154 square meters.

This technology allowed increasing the storage capacity, improving storage logistics, reducing time spent on products reception and shipment. For example, transfer of the tyres from the factory and the warehouse to transportation is carried out automatically which allows significantly reducing manual labour in the production process.

The volume of investments in the project exceeded 2.5 billion rubles. Today 1,550 people work at the enterprise, including the new warehouse.

Executive Vice President of Nokian Tyres Concern, Head of Russia and Asia Business Department, Global Marketing Andrey Pantyukhov emphasized that today this is the most modern tyre warehouse which doesn’t have any analogues in Russia and in the world. Today the factory in Vsevolozhsk is the main production site of the Concern – 82% of all passenger car tyres of Nokian Tyres were produced at the factory in the first quarter of 2021.

Reference

Nokian Tyres factory in Vsevolozhsk manufactures car tyres for passenger cars, SUVs and light trucks.

The factory was opened in Vsevolozhsk in 2005 and today it is the largest tyre factory in Russia. The production lines have the latest high-tech equipment, all processes are automated. The full-cycle factory works 24/7.